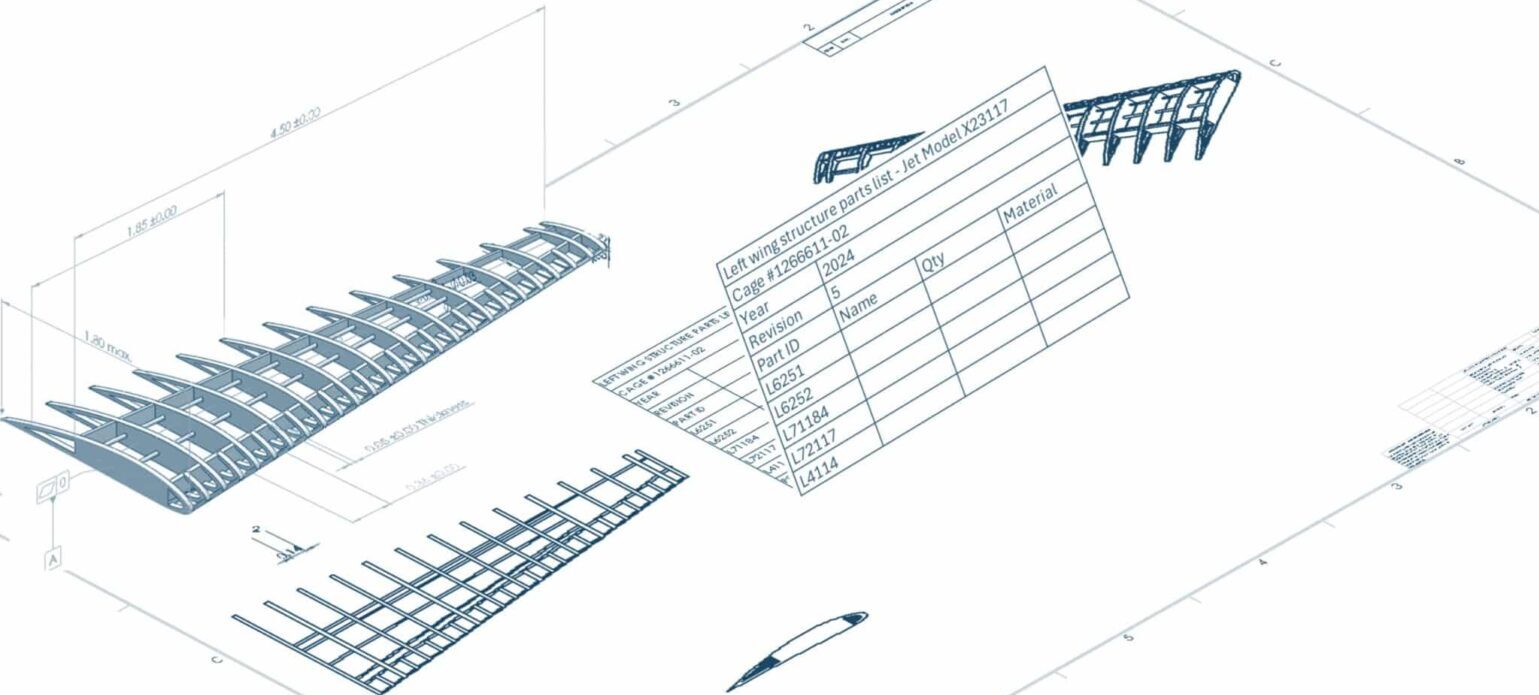

Why Static Analysis Isn’t Enough: The Hidden Failure Modes in Your Design

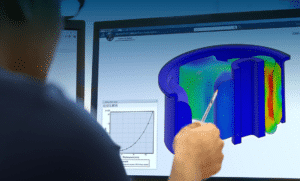

Let’s explore how SOLIDWORKS Simulation can reveal critical failure modes beyond just yield strength—and why stopping at a static study might cost you in product reliability, warranty claims, and customer satisfaction.